Shop by Category

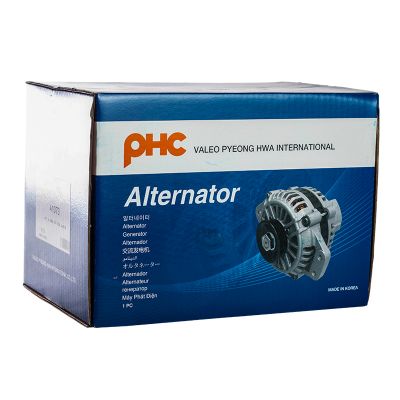

ABES Technoseal the leading Automotive Spares Importer

BEST SELLING ITEMS

AS FEATURED AT

John SmithPorto CO SEO

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum molestie, massa ut semper egestas, ex ligula ifend neque, eget pharetra elit lectus ac ex.risus.

Bob SmithPorto CO SEO

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum molestie, massa ut semper egestas, ex ligula ifend neque, eget pharetra elit lectus ac ex.risus.

FROM THE BLOG

25-FEB-2019

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras non placerat mi. Etiam non...

26-FEB-2019

Leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with...